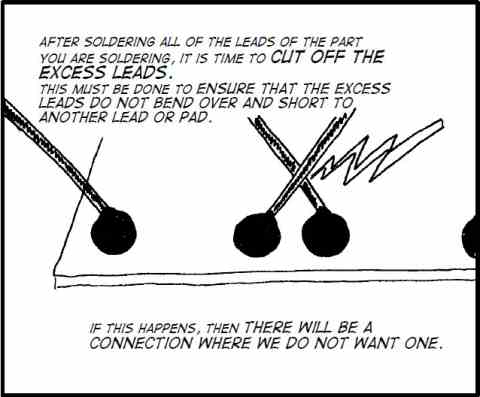

Cutting The Component Leads After Soldering

Learn to solder and create your dreams in electronicsSee the full range of soldering irons and stations at Amazon Download a pdf copy of this excellent soldering comic from mightyohm.com

You may want to cut the leads before you solder the joints. This allows you to form solder beads that cover and protect the cut end of the lead wire. It can look neater and is arguably more reliable because the end of the lead isn't exposed but it also means that it's harder to spot any connections that you have missed.

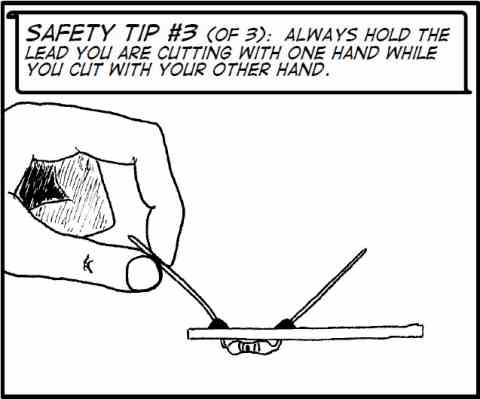

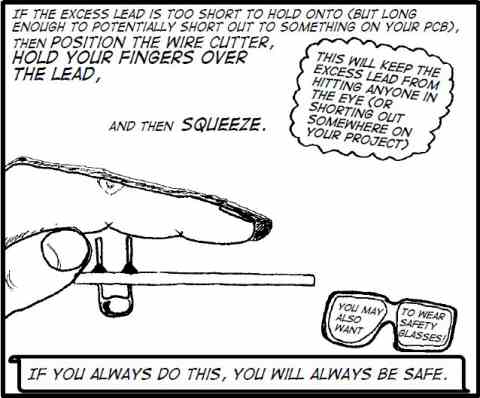

Oh yes, getting stung in the eye by a high velocity component lead is not fun, believe me. Always face the lead away from you and anyone else in the room before cutting. If you don't want to get shouted at for leaving bits of wire all over the floor then hold the free end of the lead as you cut it to prevent it from being launched across the room. We are told nowadays that we should wear eye protecting goggles while doing this work and they have a point.

I must know loads by now then because I've made more than my fair share of mistakes over the years. Especially the embarrassing episode of the exploding power supply but that's a story for another time. |

| Now subscribe to our newsletter and don't miss a thing |

|

|

Comments

No comments yet.Add Comment